With nearly a decade of experience in racing and over eight years as a professional pit crew mechanic and fabricator, Ben Baker brings a lifelong passion for vehicles to his engineering career. He combines hands-on motorsports expertise with a practical, design-focused approach to developing innovative and reliable engineering solutions.

Recent Projects

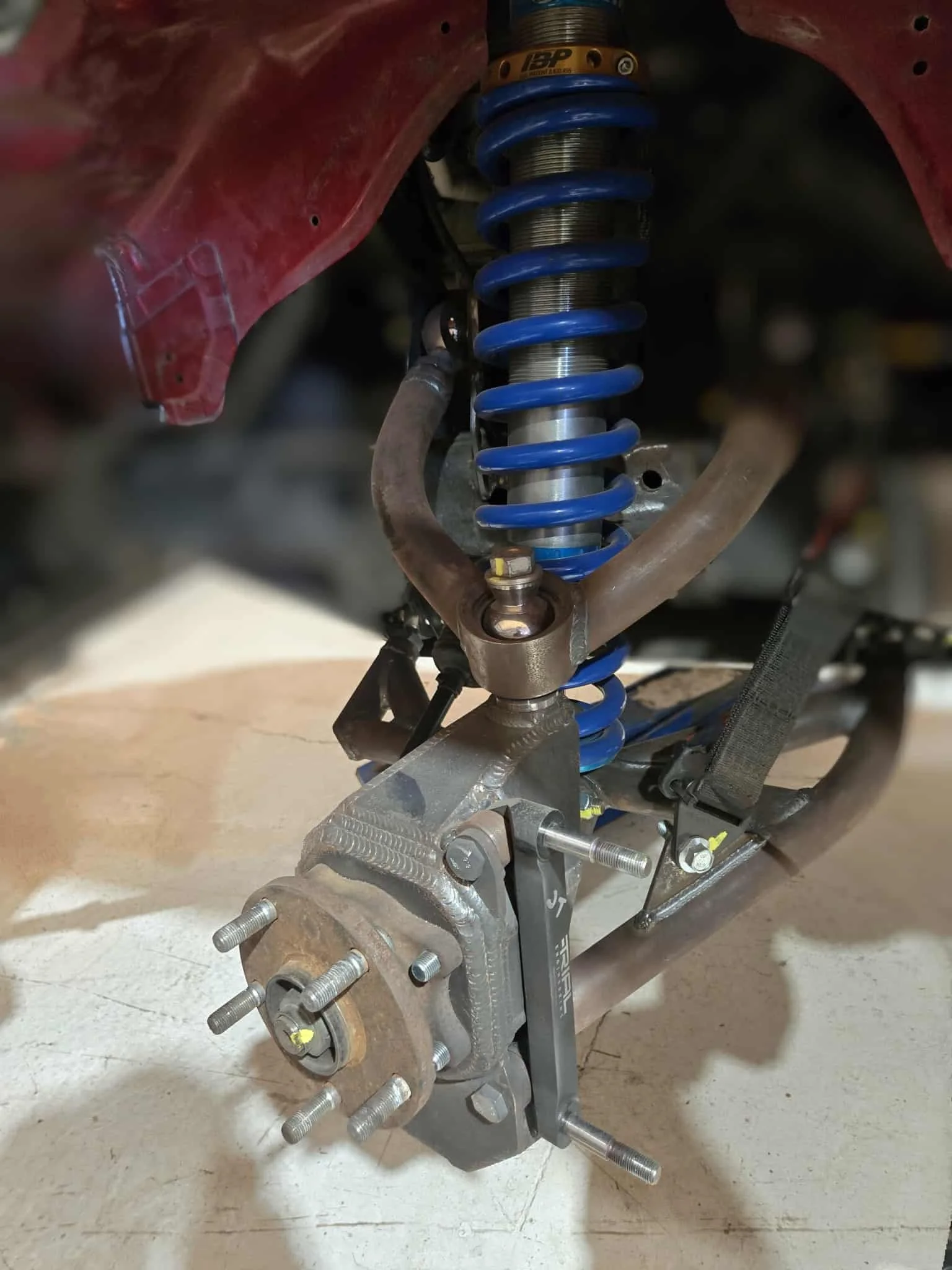

Rally Truck Front Suspension

Description

Custom front suspension system for a rally-prepped 2006 Chevy Colorado, including uprights and aftermarket brake integration.

Built to increase suspension travel and track width with a focus on improved durability, handling, and compliance under demanding rally conditions.

Development

Utilized 3D scans of the frame and OEM upright as a foundation to design custom suspension arms and uprights.

Modeled suspension geometry using SolidWorks, lowering the upper control arm by 1.5 in to increase wheel clearance.

Created both metal and 3D-printed welding jigs to ensure symmetry and repeatability in manufacturing control arms.

Produced fabrication-ready parts using CNC plasma cutting and contributed to TIG welding during final assembly.

Completed all work under tight project deadlines while ensuring accuracy in packaging and fitment.

Results

Extended track width by +1.85 in per side (3.7 in total) for greater lateral stability.

Increased suspension travel from 3 in to 9 in, tripling wheel articulation and enabling the truck to handle jumps and rough terrain.

Delivered a fully integrated, competition-ready suspension and brake system that can easily be remanufactured.

Rally Car Brake System (OEM Manufacturer)

Description

Led the complete design and integration of a high-performance brake system for the HRC Honda Civic Type-R rally build for SEMA.

Tasked with fitting a full PFC caliper and rotor package into a severely constrained 15-inch wheel assembly, downsized from the stock 19-inch configuration while preserving braking performance and thermal capacity.

Took full ownership of the design and build process, coordinating manufacturing, validation, installation, and on-vehicle testing.

Development

Designed all caliper brackets, rotor hats, and clearance envelopes using Fusion 360 and SolidWorks, referencing OEM suspension schematics and integrating supplier-provided PFC CAD models that were modified for custom fitment.

Utilized 3D scanning of the hub and suspension assembly to ensure accurate packaging, and validated geometry through FDM 3D-printed prototypes before machining.

Created GD&T drawings for fabrication, managed supplier sourcing and cost optimization, and coordinated manufacturing of components at low cost without compromising quality.

Performed hydraulic calculations to select proper master cylinder sizes for optimal brake balance and pedal feel.

Assembled and validated the final brake system, collaborating directly with OEM engineers and aftermarket partners to confirm manufacturability and performance compliance.

Results

Delivered a fully functional, production-ready brake package that achieved professional motorsports braking performance within the tightest packaging constraints of any prior configuration for this platform.

Improved manufacturability and serviceability through simplified bracket geometry, optimized tolerances, and consistent hardware interfaces.

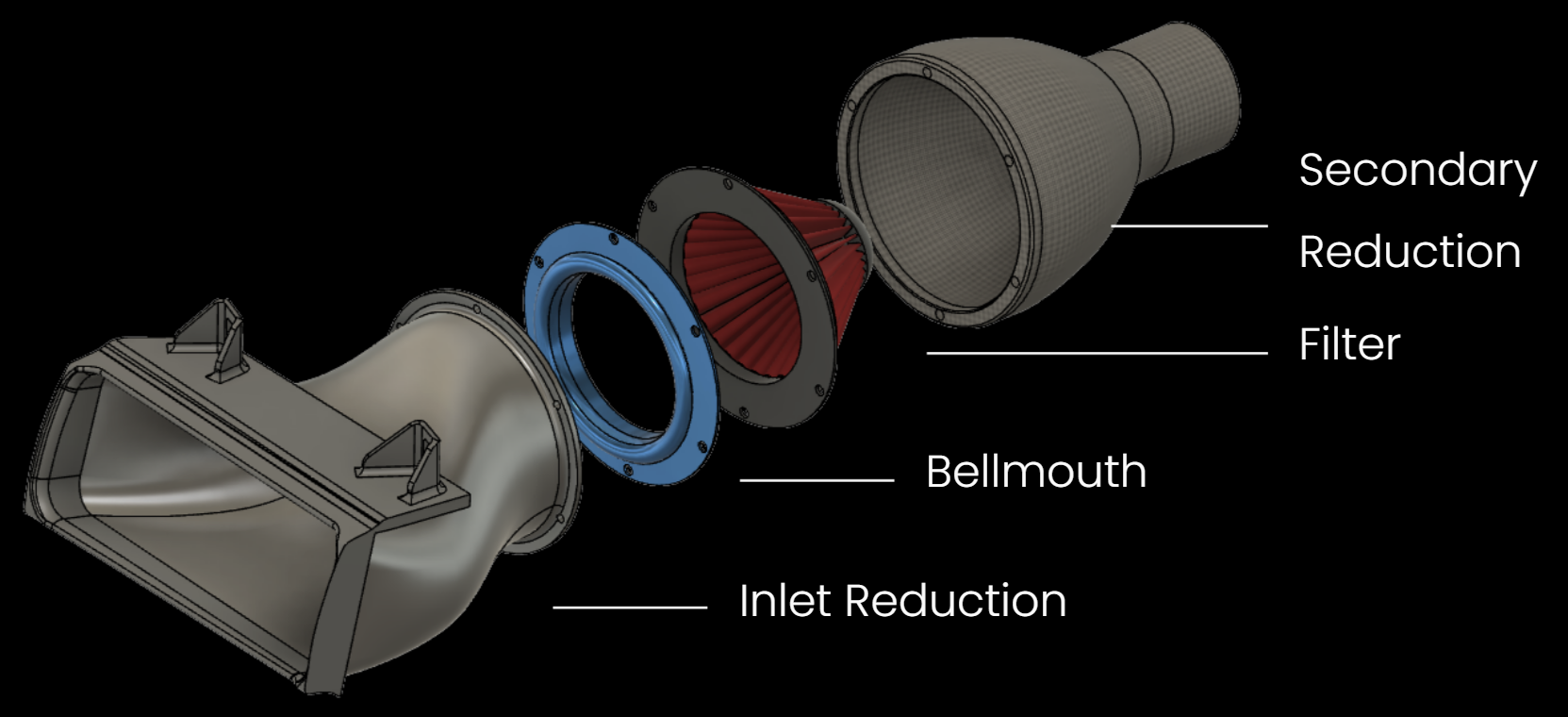

Racecar Intake Enclosure

Description

Pre-manifold intake system for a BMW E36 endurance racecar designed to increase airflow velocity and improve engine performance.

Targeted packaging constraints while maintaining structural durability under racing conditions.

Development

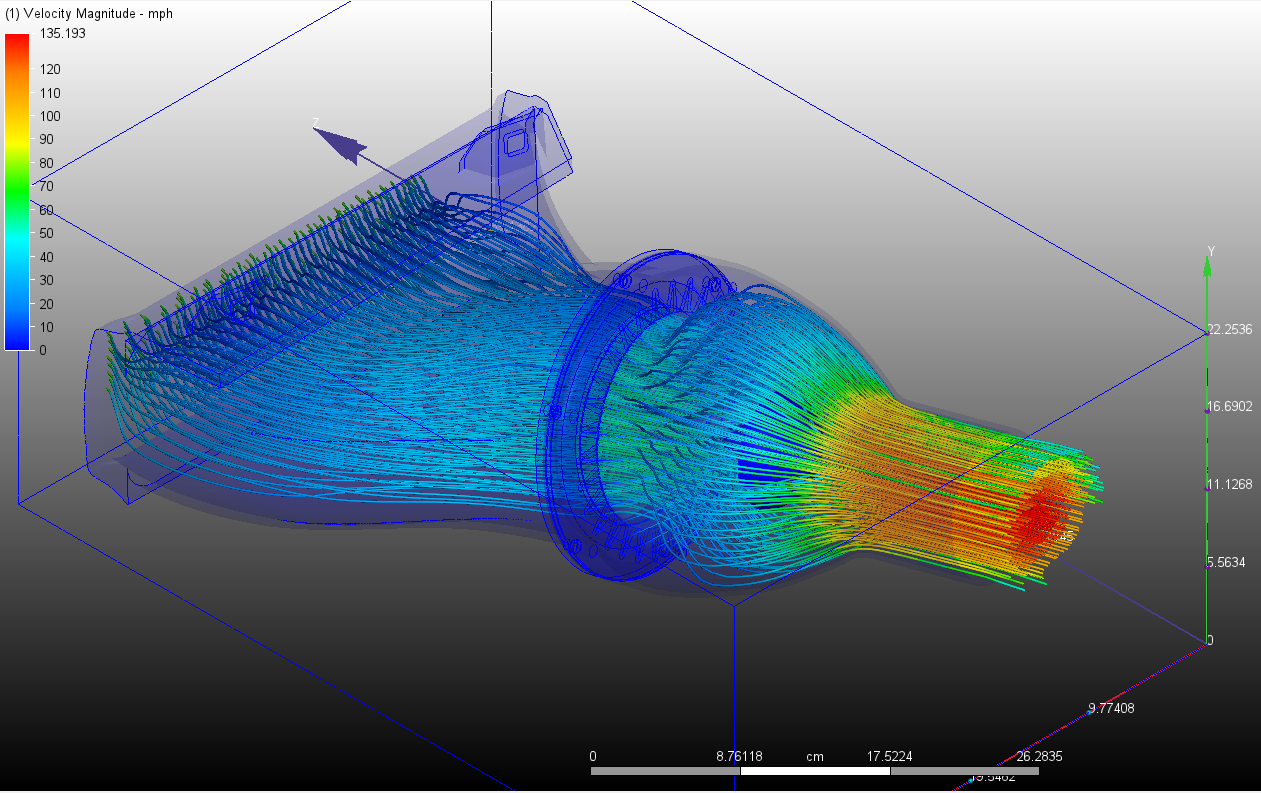

Used 3D scanning and Fusion 360 for CAD modeling within tight space limitations.

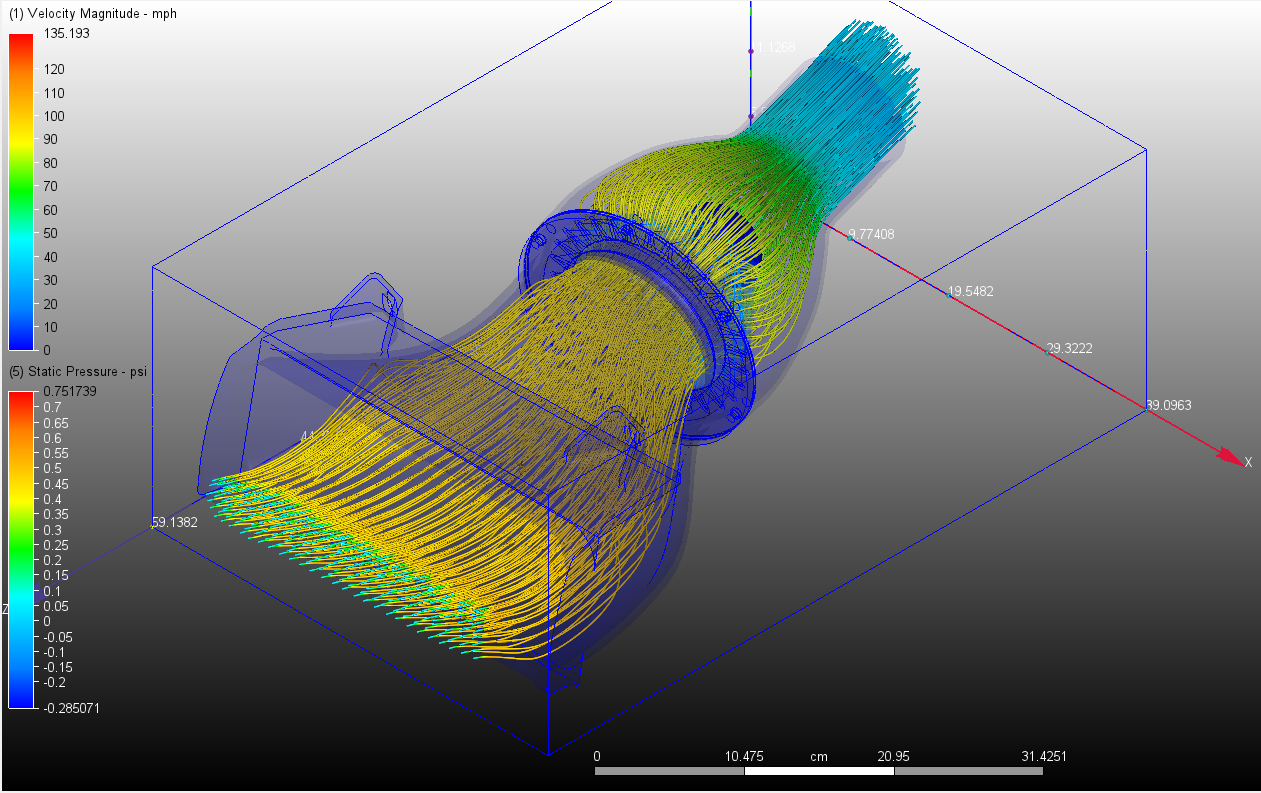

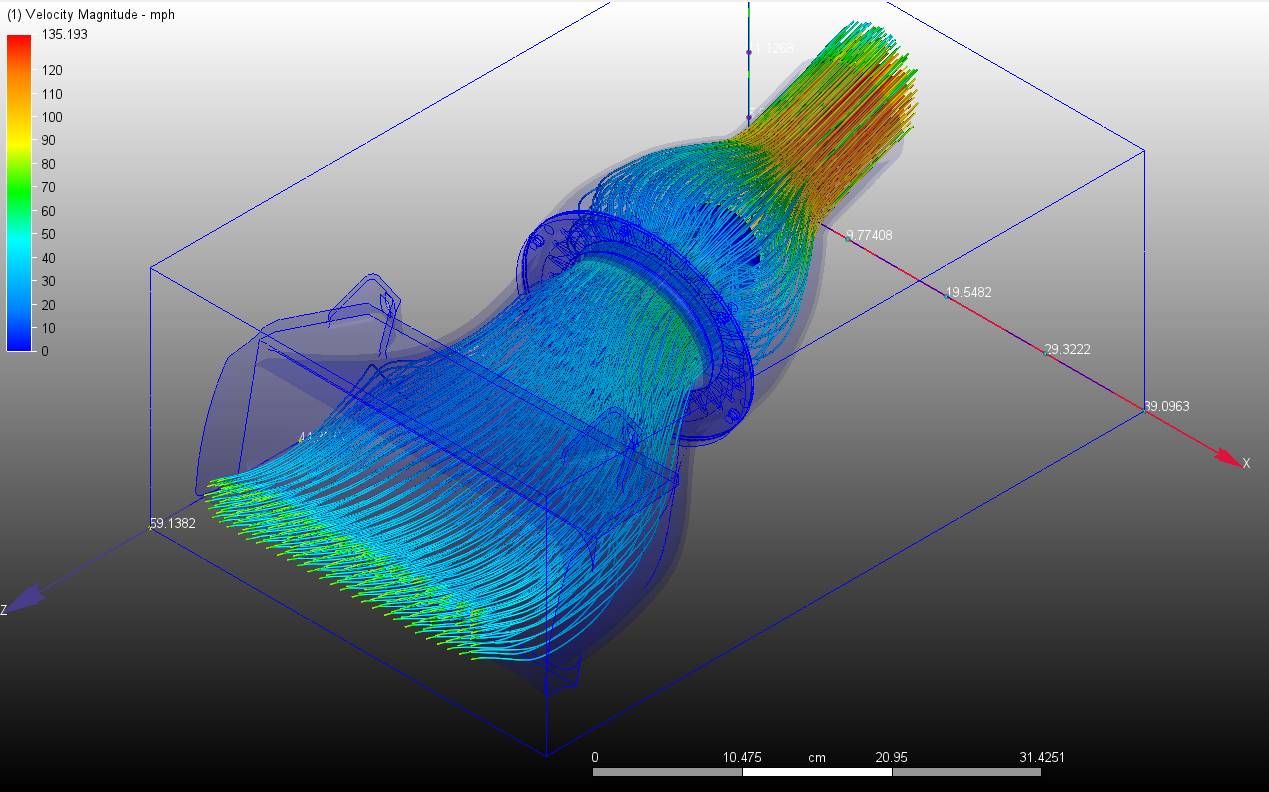

Performed CFD simulations (Autodesk CFD) to optimize airflow characteristics.

Validated designs with IAT and MAF sensor data, closing the loop between simulation and track performance.

Results

Increased intake velocity from 36 m/s (80mph) to 60.3 m/s (135 mph).

Contributed to back-to-back 1st-place podium finishes in endurance racing.

Demonstrated effective CAD-to-track workflow, integrating scanning, simulation, and real-world validation.

Silent Communications Interface

Vehicle-Side

Crew-Side

App Function:

Description

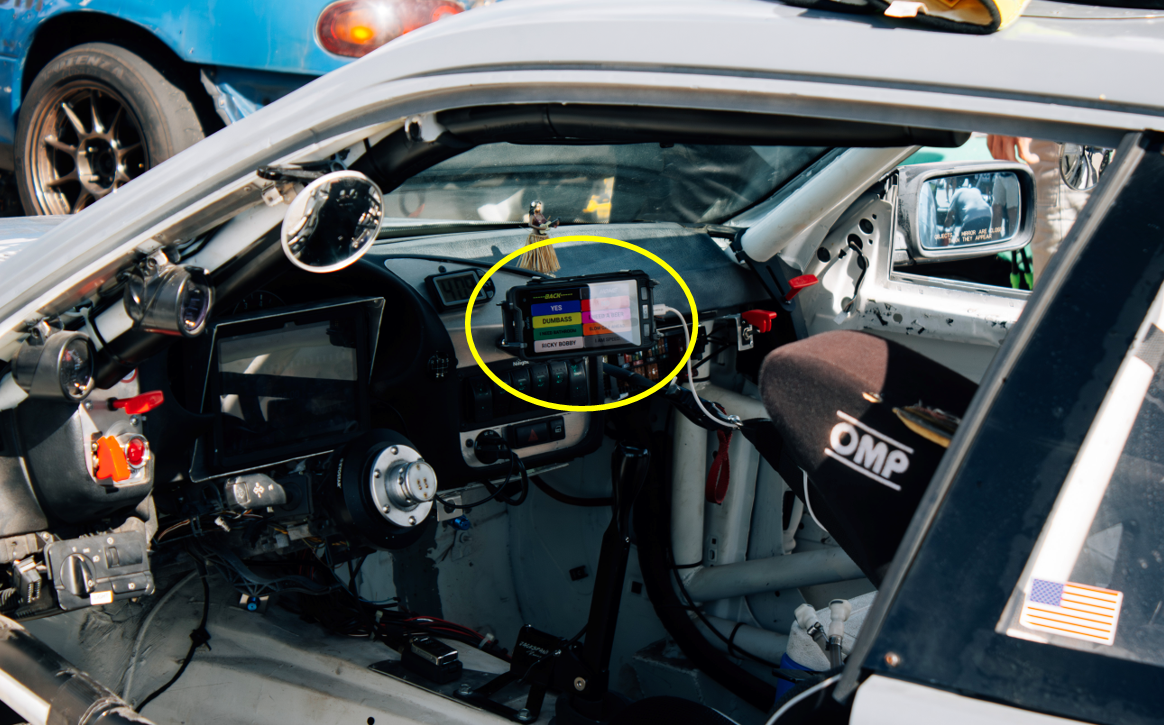

Assistive communication system replacing radios with BLE-to-SMS messaging for racecar drivers who are deaf and hard-of-hearing.

Steering wheel–mounted 11-button input interface transmits preset messages; dashboard device displays incoming crew alerts in high-visibility text.

Development

Programmed in MIT App Inventor (BluetoothLE API) and Arduino IDE for the Adafruit ItsyBitsy nRF52840 (BLE 5.0).

Integrated embedded firmware, Li-ion power management, and BLE communication into a compact steering wheel module.

Designed button/electronics housing in Fusion 360, with 3D printing for prototyping and CNC machining for final fabrication.

Implemented a trusted-numbers system for secure filtering and a hardware interrupt (Dismiss button) for safe acknowledgement.

Results

Delivered the first HMI comms system for deaf drivers, bridging embedded hardware and mobile app development.

Improved reliability and fault tolerance over traditional radios through BLE-to-cellular integration.

Validated in on-track functional testing, demonstrating low latency, robustness, and ergonomic usability under racing conditions.

Modular Roof Rack with Pneumatic Sunroof

Description

Conceptual roof rack system for the 5th Gen Toyota 4Runner, featuring perpendicular T-slot crossbars for versatile cargo mounting.

Integrated a pneumatic sunroof cover that can be opened and closed from inside the cabin, eliminating the need for external adjustment.

Engineered for structural durability under off-road vibration and loading conditions.

Development

Modeled the full assembly in Autodesk Inventor, applying parametric design and multi-body part modeling.

Incorporated supplier hardware CAD models to validate fitment, clearances, and attachment points.

Designed custom linkage and bracket systems with attention to DFMA principles (Design for Manufacturability and Assembly).

Results

Produced a detailed CAD concept demonstrating a unique aftermarket roof rack solution with an integrated, in-cabin sunroof cover.

Validated feasibility through digital modeling and simulation, ensuring proper fitment and motion without physical prototyping.

Highlighted potential improvements in user convenience and modularity compared to existing 4Runner roof racks.